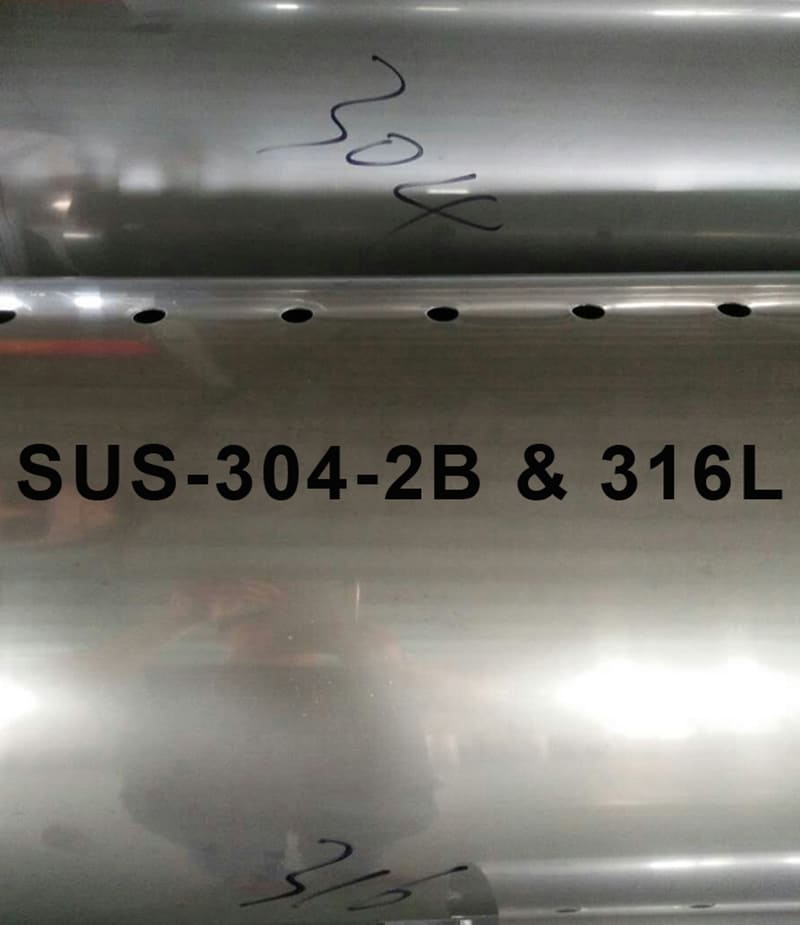

Marine-grade 316L stainless steel solar hot water systems offer superior corrosion resistance, enhanced durability, and long-term performance in harsh environments, making them a top choice over SUS-304 for pressurized solar geysers. Ideal for coastal areas, 316L ensures maximum reliability and extended lifespan

| Model: | Solar Vacuum Tube | Aperture Area | Gross Area | Capacity | |

| Item No. | Qty /【pcs】 | Size /【mm】 | 【M2】 | 【M2】 | 【L】 |

| Diehard-100L | 10 | Φ58 X 1800 | 0.94 | 1.546 | 100 |

| Diehard-150L | 15 | Φ58 X 1800 | 1.395 | 2.319 | 150 |

| Diehard-200L | 20 | Φ58 X 1800 | 1.874 | 3.092 | 200 |

| Diehard-300L | 30 | Φ58 X 1800 | 2.811 | 4.632 | 300 |

| DieHard 316L Stainless Steel Compact High Pressure Solar Hot Water | ||

| 1 | Model | DieHard Serial |

| 2 | Water Tank | |

| 3 | Material of Outer Tank Shell | High Quality Stainless Steel Plate |

| 4 | Material of Inner Tank Chest | Marine Grade 1.5mm thick 316L Stainless Steel |

| 5 | Water Tank Diameter | 【360/470 mm】 |

| 6 | Water Tank Insulating Layer | High Density Polyurethane,【55mm】 |

| 7 | Vacuum Tube | |

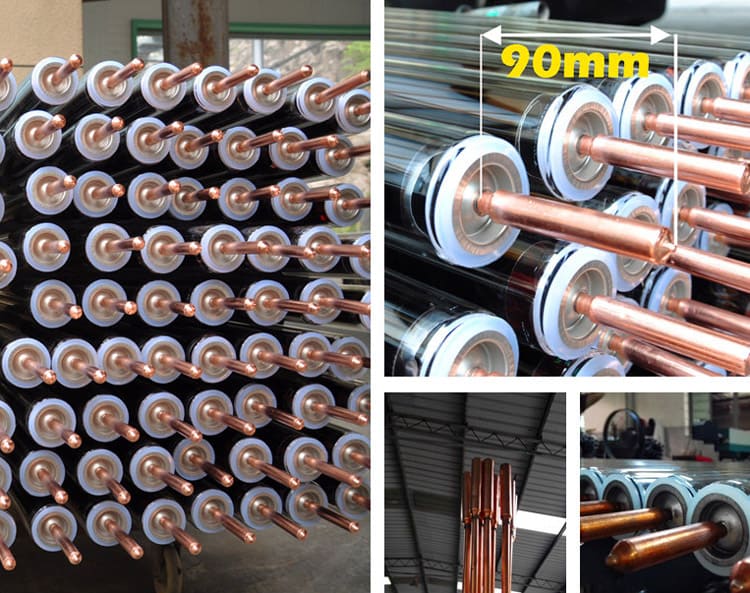

| 8 | Tube Structure | All-Glass Double-Tube Co-Axial Structure |

| 9 | Glass Material | High Borosilicate 3.3 glass |

| 10 | Tube Size | 58*1800mm * 24 Tubes |

| 11 | Coating Material | 【Cu/SS-ALN(H)/SS-ALN(L)/ALN】 |

| 12 | Sediment Method | Tri-Element Magnetron Sputtering Plating |

| 13 | Absorb Ratio | 0.93-0.96> 92% (AM 1.5) |

| 14 | Emission ratio | 0.04-0.06(800C±50C) |

| 15 | Heat Pipe | |

| 16 | Heat Pipe Material | TU1 Copper |

| 17 | Heat Pipe Condenser Size | 【Ø14mm Diameter】【90mm Length】 |

| 18 | Heat Pipe Body Size | Ø8mm Diameter |

| 19 | Riwatt Heat Pipe Pocket | 【316L STAINLESS STEEL】 |

| 20 | Heat-Transfer-Fins | Premium Complete Type (Super Model) |

| 21 | Max.Working Temp | -37 ~250C |

| 22 | Start-up Temp. of Heat Pipe | <=30C |

| 23 | Working Pressure | 0.7Mpa. |

| 24 | Testing Pressure | 1.2Mpa. |

| 25 | Daily Efficiency | 55% |

| 26 | Heat Pipe Material | TU1 Copper |

| 27 | Bracket | |

| 28 | Bracket Material | Stainless Steel / Galvanized Steel /Al.Alloy |

| 29 | Bracket Angle | 30° |

| 30 | Bolts & Nuts | Stainless Steel |

● The heat pipe pressurized solar heater tank has no exhaust hole,therefore,it must bear the pressure come from tap water and hot water,when use,the hot water comes out because of water pressure.

● Vacuum tube absorbs solar energy,and conductive copper pipe transfers the heat into the pressurized solar water heater tank,In this case,the water inside the tank becomes hot.

●No water in the heat pipe makes the whole system can bear pressure.

● Start up quickly, heat pipe transfer the heat energy into the storage tank swiftly.

● Withstand pressure of max 10bar, can be connected with city water directly, work automatically

● The storage tank and the heat pipe mechanical sealed, the solar water heater can still work even withseveral tubes breakage.

● With reasonable design and choose excellent material, the inner tank is without any breakage afterone hundred thousand time’shigh pressure testing.

● High density polyurethane foam, well insulation.

● Can be installed in series and parallel to be a solar hot water system.

● Can be connected with gas water heater and small boiler, also can preheat the water in advance.8. Can be installed in anywhere ( for example, you can install the solar water heater on the ground ofthe garden, and use the hot water on the third floor).

● Transfer the heat energy quickly, we use special medium in the heat pipe and it can transfer the heatenergy more than 1000 times faster than copper.

● Highly efficient absorber, it increase 20% or more than ordinary solar water heater.

● No water and no water scale inside the evacuated tubes, the tubes will not be cracked even ifduring -40 Degree..

● Withstand pressure of 0.7 Mpa, can be connected with the city water directly.

● Can still work even with several tubes breakage. The water will not flow out from the storage tank.6. Can be used in sunny days even if in the extreme cold climate.

1. With ADJUSTABLE bracket

(suitable for both flat roof and sloop roof).

2. New designed vacuum tube holder.

3. New design electric element cover.

4. 316L stainless steel inner chest – marine grade/superior anti-rust performance.

The 316l stainless steel alloy is used in various applications because it’s great at avoiding weld corrosion. It can also withstand high temperatures and it has a high melting point at around 2,500 degrees Fahrenheit or about 1,370 degrees Celsius.

Pros: Stronger than 304 stainless.

Cons: Requires the right tools to machine well.

Pros: Extremely corrosion resistant and performs well against pitting.

Cons: More expensive than 304.

Pros: Resistant to salt water and caustic chemicals.

Cons: Less formable and machinable than 304.

●316L stainless steel contains molybdenum, which significantly enhances its resistance to corrosion, especially in harsh environments like coastal areas where saltwater exposure can cause rapid corrosion. SUS-304 is more susceptible to corrosion in such conditions.

●316L is less likely to rust or corrode, ensuring a longer lifespan for solar geysers, especially in marine or industrial settings.

●316L can withstand higher temperatures and pressure compared to SUS-304, making it more suitable for pressurized solar water heaters.

●It is also better at handling aggressive chemical environments, such as areas with high chloride levels in the water.

●316L is more resistant to pitting and crevice corrosion, common in harsh outdoor environments.|

●It is also more resistant to acid and alkali corrosion, giving it better longevity.

Stainless steel of both types is non-reactive with water, meaning it won’t alter the taste or quality of the water. However, 316L is often considered more hygienic due to its higher resistance to microbial growth.

The durability of 316L steel means it requires less maintenance and fewer replacements over time, which is more cost-effective in the long run.

●316L Stainless Steel is typically more expensive than SUS-304 due to its enhanced properties and superior corrosion resistance.

●The cost of a 316L stainless steel solar water heater is generally 10-30% higher than an equivalent SUS-304 system, depending on factors like the manufacturer, size of the unit, and design specifics.

To get an accurate price for a solar geyser system, it’s best to request a quote directly from the supplier, as the price can vary widely based on local market conditions, shipping, and bulk purchasing.

Sorry, no posts matched your criteria.

You can contact us any way that is convenient for you. We are available 24/7 via fax, email or telephone.

WhatsApp us