1. Dual Vacuum Super Conductive Tube Introduction

Working Principle of Dual Vacuum Super Conductive Tube (DVT)

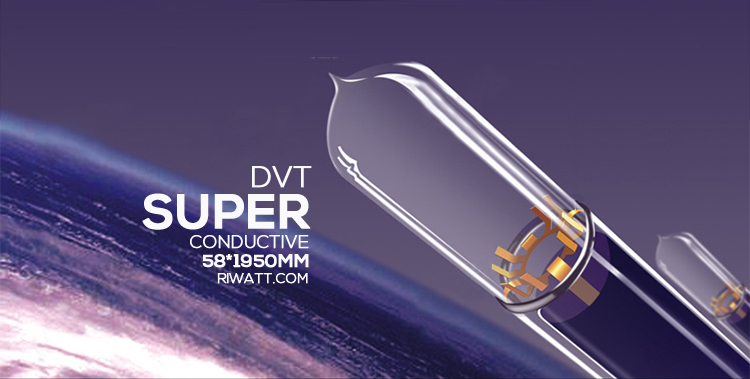

The Dual Vacuum Super Conductive Tube (DVT) is an advanced solar heat collection technology made from high-transmittance borosilicate ultra-hard glass through a precision manufacturing process. It features a double-layer outer tube and a single-layer inner tube, with a high-vacuum insulation layer between them. The inner cavity maintains a low vacuum, forming a dual-vacuum sealed structure that delivers exceptional heat collection and transfer efficiency.

The DVT assembly includes an outer glass tube coated with a multi-metal carbonized sunlight-absorbing film (SS-ALN/CU). This coating offers excellent high-temperature stagnation resistance and superior aging durability. Inside, a spiral suspension core is filled with a conductive working fluid, ensuring efficient heat exchange performance.

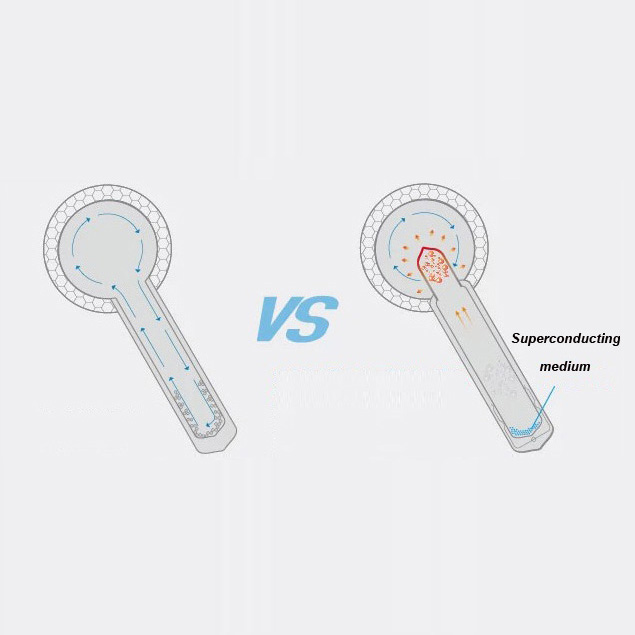

One end of the DVT serves as the evaporation section (solar collector area), while the opposite end functions as the condensing section (heat exchange area).

When sunlight heats the evaporation section, the working fluid vaporizes and rapidly flows toward the condensing section due to the pressure difference. There, it releases heat energy, condenses back into liquid, and returns along the tube wall to the evaporation section — completing a continuous super-conductive circulation cycle.

Through this phase-change heat transfer mechanism, the DVT tube achieves ultra-fast, stable, and efficient heat transmission, making it ideal for high-performance solar water heaters and industrial solar applications.

Dual Vacuum Super Conductive Tube Technical Parameters

| DVT Vacuum Tubes Technical Parameter | |||||

| 1 | Material | Borosilicate glass 3.3 | |||

| 2 | Outer Tube Diameter | Φ47±0.7mm, thickness:1.6mm | |||

| Φ58±0.7mm, thickness:1.6mm | |||||

| 3 | Inner Tube Diameter | Φ37±0.7mm, thickness:1.8mm | |||

| Φ47±0.7mm, thickness:1.8mm | |||||

| 4 | Length | Φ47-1620mm Φ58-1950mm | |||

| 5 | Condensing Section Length | Φ47-1500mm = 120mm±5mm | |||

| Φ58-1800mm = 150mm±5mm | |||||

| 6 | Base Material | Cu/SS-AIN(H)/SS-AIN(L) | |||

| 7 | Deposition Method | Triple-target magnetic sputtering | |||

| 8 | Absorption Ratio(after Coating) | 0.93-0.96(AM1.5) | |||

| 9 | Emission Ratio | 0.04-0.06(80°C±5°C) | |||

| 10 | Vacuum between Inner Tube and Outer Tube | P≤1.0×10¯³ (Pa) | |||

| 11 | Vacuum in Inner Tube | P≤3.0×10¯³ (Pa) | |||

| 12 | Average Heat Loss Coefficient | ULT= 0.4-0.6w/( m².°C) | |||

| 13 | Amount of Solar Radiation under Stagnation | H=3.7-4.2 MJ/m² ( 58mm) | |||

| H=2.9-3.2MJ/ m² (47mm) | |||||

2.The heat transfer of the working liquid in the DVT tubes includes four links:

1. At the heating section of the heat tube, the working liquid in the tube is gasified by an external heat source;

2. Due to pressure difference between the heating section and the condensing section of the tube, the steam moves toward the condensing section;

3. At the condensing section, the heat released by the steam in the tube is brought away by the external cold medium, and the steam is condensed into liquid which flows back to the evaporation section by gravity;

4. Under the action of the absorption suspension core, the condensing liquid is re-heated and gasified, and the circulation goes round and round.

3.Dual Vacuum Super Conductive Tube Basic Characteristics

1). Superior thermal conductivity.

In the heat tube, the heat is transferred mainly by phase change of the working liquid and the flowing of the steam, the thermal resistance is small, so that the heat tube has quite high heat conducting capability; and compared with the metal with higher heat conductivity such as silver, copper, aluminum, etc., the heat tube with unit weight can transfer more heat;

2). Superior isothermal property.

The steam in the inner cavity of the heat tube stays in the saturated state, so when the steam flows from the evaporation section to the condensing section, there is little pressure drop as well as temperature drop;

3). Variable density of heat flow.

The density of heat flow in the inner tube can be changed by modifying the heating surface of the condensing section or the evaporation section.

Dual Vacuum Super Conductive Tube (DVT) Introduction

4.The heat transfer of the working liquid in the DVT tubes includes four links:

1. At the heating section of the heat tube, the working liquid in the tube is gasified by an external heat source;

2. Due to pressure difference between the heating section and the condensing section of the tube, the steam moves toward the condensing section;

3. At the condensing section, the heat released by the steam in the tube is brought away by the external cold medium, and the steam is condensed into liquid which flows back to the evaporation section by gravity;

4. Under the action of the absorption suspension core, the condensing liquid is re-heated and gasified, and the circulation goes round and round.

5.FAQ for Dual Vacuum Super Conductive Tube:

1. What Is A Dual Vacuum Super Conductive Tube?

A Dual Vacuum Super Conductive Tube is a high-efficiency solar heating tube made of borosilicate ultrahard glass. It features a double-layer design with a high-vacuum sandwich layer between the inner and outer tubes, and a low-vacuum inner cavity, enhancing thermal insulation and heat transfer efficiency.

2. What Are The Advantages Of Dual Vacuum Tubes Over Standard Solar Tubes?

Superior heat retention due to double vacuum layers

High light transmittance for maximum solar absorption

Excellent durability and resistance to pressure and temperature changes

Suitable for high-efficiency solar water heating systems

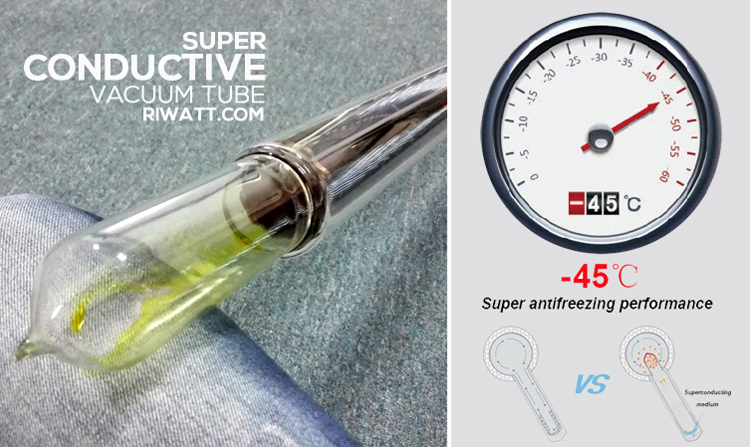

3. Can These Tubes Be Used In Cold Or Freezing Climates?

Yes. The dual vacuum design minimizes heat loss, making them highly effective even in low-temperature environments.

4. How Long Do Dual Vacuum Super Conductive Tubes Last?

With proper installation and maintenance, these tubes can last 15–20 years or more, maintaining high thermal efficiency throughout their lifespan.

5. Are These Tubes Compatible With Existing Solar Water Heaters?

Yes. They can often be retrofitted into existing systems or used in new installations, but compatibility should be confirmed based on collector type and system design.

Leave A Comment

Your email address will not be published.